Basic Carbon Inventory Process: Core Steps from Boundaries to Calculation

A complete carbon inventory generally includes four steps:

1. Determine Inventory Boundaries

Companies need to clarify which activities, locations, and organizational units will be included in the inventory. Common bases for judgment include:

- Company organizational structure

- Asset/operational control

- Local regulatory requirements

- Customer or supply chain requirements

Clear boundaries ensure consistency in subsequent data and activity lists.

2. Data Collection

Data collection typically covers:

- Electricity and fuel consumption records

- Production or operational activity data

- Raw material usage

- Outsourced activity information (e.g., transportation, waste)

This is an important foundation for significance assessment, as all identification factors are built on "whether activity information is complete."

3. Emission Calculation

Through inventory systems or professional tools, activity data is converted into emissions. Usually, emission factors from various countries are referenced (e.g., Ministry of Environment, IPCC, Ecoinvent, etc.).

4. Inventory Analysis

Finally, determinations must be made regarding:

- Which emission sources account for the largest proportion

- Which activities pose management risks

- Which emissions will receive high attention from stakeholders

Definition of Carbon Inventory Significance Assessment: Identifying the Emission Sources Companies Really Need to Focus On

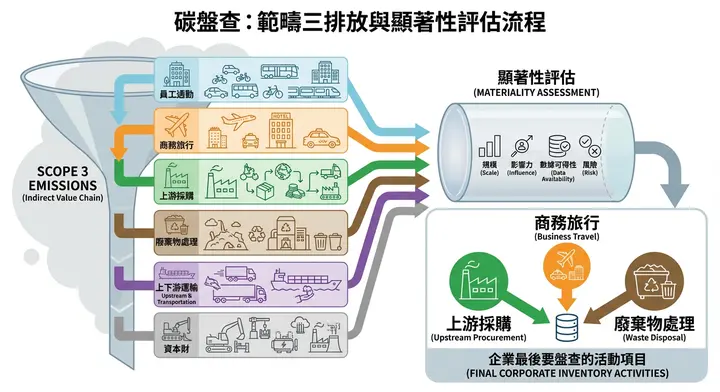

Significance assessment is a systematic identification procedure aimed at finding the indirect emission sources with "the highest impact" in company operations. Its core value lies in helping companies identify the relative importance of various activities to carbon emissions, focusing not only on emission size but also considering risks, regulations, management capability, and stakeholder attention, making the overall inventory process more strategic and complete.

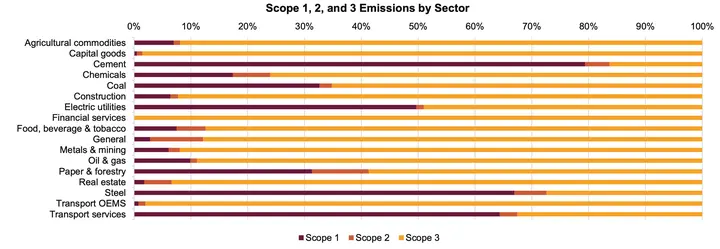

In practice, significance assessment is particularly applicable to evaluating Scope 3, as external activities, supply chain processes, logistics, and product use phases often generate significant emissions. For most industries, Scope 3 emissions can even account for over 70% of total corporate emissions, often far exceeding Scope 1 and Scope 2. Therefore, without systematic significance assessment, companies often struggle to grasp truly impactful emission hotspots.

Its purposes include:

- Focusing on the most critical emission sources, especially high-proportion Scope 3 items

- Determining inventory data collection priorities

- Enhancing inventory transparency and consistency

- Ensuring inventory results are representative with limited resources

Significance assessment is also presented through scoring, weighting, and ranking, enabling staff to objectively explain "why these emission sources were selected" and clearly explain the key role of Scope 3 in the overall carbon footprint.

(Source: CDP Technical Note: Relevance of Scope 3 Categories by Sector)

How to Conduct Significance Assessment

Step 1: Establish an "Activity Inventory"

First, list all activities that might fall within the inventory scope, such as:

- Equipment use

- Outsourced transportation

- Product distribution

- Waste treatment

- Supplier material use

The more complete the activities, the higher the assessment accuracy.

Step 2: Select Significance Identification Factors

Common identification factors may include:

- Emission proportion

- Regulatory or contractual requirements

- External attention (customer/supply chain requirements)

- Management controllability

- Operational risk

- Data collection feasibility

Companies can weight these according to their needs.

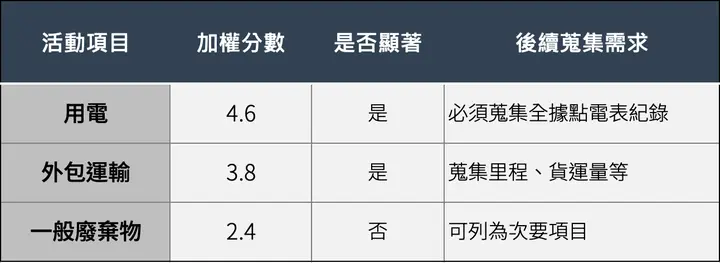

Step 3: Set Scoring Methods and Thresholds

Scoring methods typically use:

- Five-level scoring (1-5 points)

- Three-level scoring (1-3 points)

Combined with weight settings, such as:

- Emissions 40%

- Compliance risk 30%

- External attention 20%

- Management controllability 10%

Those with weighted scores above the threshold are considered "significant emission sources."

Step 4: Team Scoring and Discussion

Cross-departmental discussion is important, for example:

- Quality assurance handles waste data

- Transportation is managed by logistics

- Equipment use is managed by engineering or maintenance

Cross-departmental assessment improves assessment completeness.

Step 5: Output Significant Activities for Subsequent Inventory

Final results typically include:

These results become the foundation for subsequent data collection worksheets.

Common Significance Assessment Indicators

The following eight indicators most commonly appear in corporate practice:

- Emission size (quantitative indicator)

- Regulatory or compliance risk

- Customer/supply chain requirements

- Stakeholder attention

- Operational risk (e.g., energy price fluctuations)

- Management capability (controllability, improvement potential)

- Data accessibility

- Alignment with corporate sustainability strategy

Depending on the industry, companies can add or remove items. For example, logistics companies might add "transportation intensity," and food service companies might add "consumable consumption."

Challenges of Carbon Inventory Significance Assessment: Three Pain Points Staff Most Often Encounter

Pain Point 1: Incomplete Activity Inventory

Many companies, when starting inventory, often overlook outsourced activities, logistics, waste, and primary supply chain activities, preventing significance assessment from reflecting actual emissions.

Pain Point 2: Non-standardized Assessment Factors

Different departments may score the same activity very differently, leading to inconsistent results.

Pain Point 3: Disconnection Between Assessment Results and Data Collection Process

Some companies complete significance assessment, but subsequent data collection still requires staff to manually rebuild tables, increasing errors and workload.

Complete Significance Assessment with DCarbon: An End-to-End Process from Identification to Data Collection

DCarbon provides the following in its significance assessment module:

1. Preset Identification Factors and Scoring Criteria

Including data accessibility, expected users, activity data quality, data collection frequency, etc. These can be used directly or customized according to company needs.

2. Ready-to-Use Activity Item Lists

The system pre-builds common inventory activities, including energy, fuel, transportation, waste, materials, refrigerants, outsourced operations, etc., without needing to create them yourself.

3. Systematic Scoring Process

The scoring interface is intuitive and supports multi-person assessment, avoiding Excel filling inconsistencies and collection difficulties.

4. Automatic Calculation of Weighted Scores and Significance Thresholds

The system can automatically score based on your weight settings and mark "significant/not significant."

5. One-Click Import to Carbon Inventory Data Collection

After completing significance assessment, all significant items can directly enter the data collection page without rebuilding tables.

This feature is especially suitable for:

- Companies conducting their first inventory without methodology experience

- Staff who need to re-inventory annually and want to save rework time

Conclusion and Call to Action

Significance assessment is not only a required process but also helps companies complete the most representative inventory at minimum cost. Through complete activity inventories, clear identification factors, and standardized scoring methods, companies can more quickly focus on emission hotspots while ensuring inventory quality.

If you want to:

- Make significance assessment more standardized

- Reduce cross-departmental data back-and-forth

- Connect significance results with carbon inventory data collection

Then DCarbon's significance assessment module is the most efficient choice.

Learn how DCarbon can help your company improve inventory efficiency: